Back in September 2015, Bruce Kelly of Farm & Food Care Ontario wrote an article for The Grower about getting wet while helping evaluate how evenly an irrigation system applied water to a vegetable field. The process involved collecting and measuring water in buckets in a grid pattern in the field for a period of time, measuring the flow rate and pressure at each sprinkler nozzle, and recording the type and condition of sprinkler nozzles used and riser pipe heights.

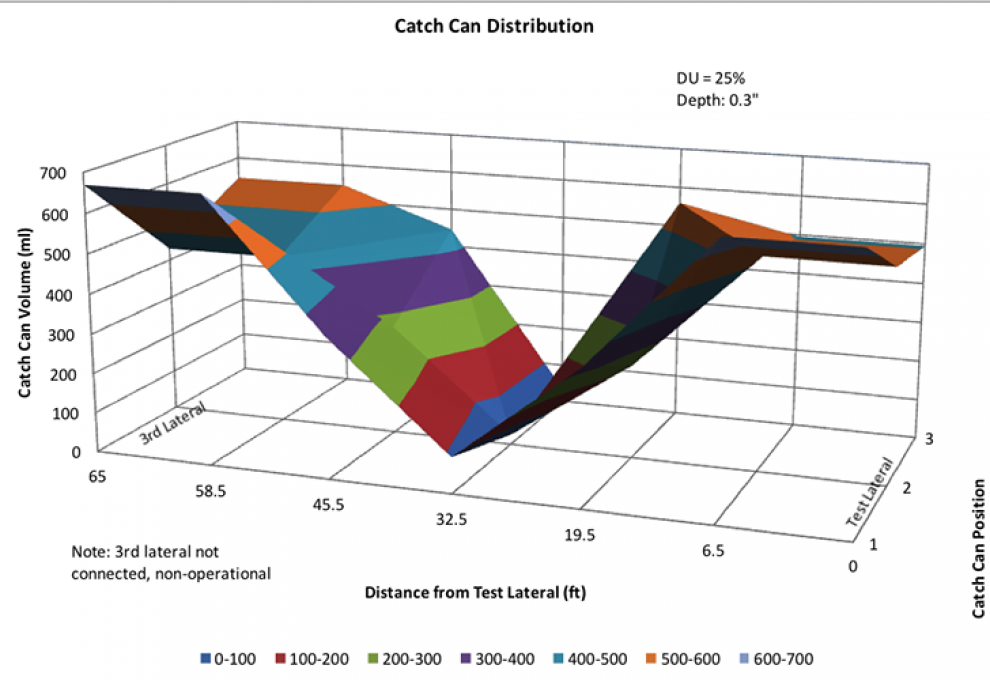

We found that the irrigation water application or distribution uniformity was not very even; in fact, it was only 25 per cent efficient. The target is 80 to 100 per cent.

What does 25 per cent mean? Well, when you finish applying what you think is one inch of water over the field, it means that some areas are only getting one-quarter of an inch of water because of virtually no overlap in water coverage. The other way of looking at it is that if you apply one inch of water to the poor overlap areas, other portions of the field will get four inches of water elsewhere.

Either those poor beets have their tongues hanging out or they are building an ark depending on which neighbourhood they ended up in. What it means to the grower is a potential variation in quality and quantity of product across the field.

Once you know that the application is uneven, ask why and what can be done to make sure the crop has the same amount to drink.

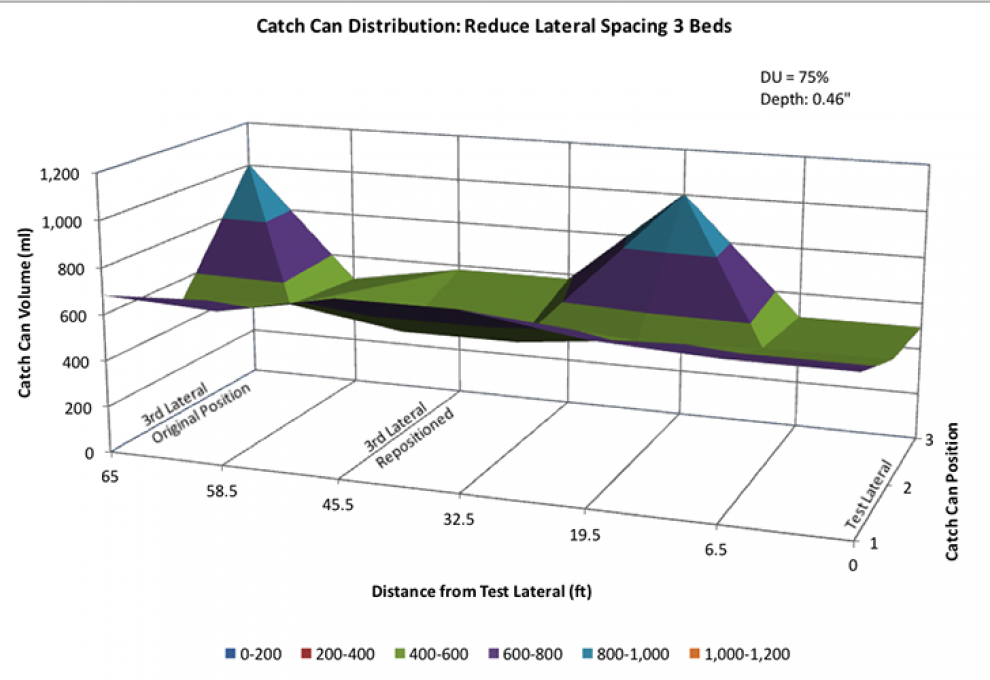

The spacing between laterals along with nozzle pressures, flow rates, conditions, and types help tell us why. In this case, moving the laterals closer together by about 20 feet improves overlap and raises the distribution uniformity to 75 per cent. Further improvement to bring the system to at least 80 per cent efficiency can be achieved by dealing with the nozzles.

The nozzle pressure dropped slightly along the lateral, but it was not significant. Variations in nozzle flow rates were not related to pressure or distance from the main. The nozzles were in reasonably good condition. The big factor was the variation in the types of nozzles used and the height of the standpipes. Most of the sprinkler heads were single nozzles; however, 18 per cent of the sprinklers had double nozzles. None of the nozzles was plugged, but one was turning slowly and one was leaking. The lateral was leaking at a standpipe connection in one area. Most of the risers were twelve inches high, but 18 per cent were 20 inches. The farm has a nozzle replacement program. This assessment highlighted that they are doing the right thing by standardizing the nozzles and replacing old or failed units. It also placed focus on standardizing the riser heights; after all, how can you get consistent application if your equipment varies?

What did we all learn?

1. The uneven application of irrigation water was not obvious to the eye. You needed to conduct the assessment to make what was happening visible.

2. Discuss the results with the grower or owner or operator to get feedback. We recommended moving the laterals closer by about three beds or 20 feet. This simple recommendation was not practical for the operation. In the end, it was decided that moving the laterals closer by thirteen feet was more practical.

3. The poor overlap has two potential implications: produce that is under-watered, or, produce that is over-watered if you want to ensure the dry areas get enough water. Either way, there may be implications to time to market, product quality and/or consistency, or crop input requirements. Over-watering means additional pump run time, which costs you unnecessary money.

4. Continue with the nozzle replacement program. The assessment drew attention to the impact the variation in nozzle types and their condition has on how even irrigation water is applied to a field. Standardization of nozzles and riser heights will help move this system from 75 per cent to at least 80 per cent distribution uniformity efficiency.

5. Irrigate when the air is still, typically early evening, early morning, or at night, to prevent the water from evaporating before it hits the ground or being blown to the neighbour’s weed-filled hedgerow.

6. Install a flow meter at the pump to measure how much water is being applied to the field or farm. A flow meter is a tool to help identify leaks, blockages, variations in the application rates for different crops (you might find out that some crops are too expensive to grow), or variations in operator application rates. By benchmarking your water use, you can identify issues or tweek your system. It is the old adage, information is knowledge.

7. If you have an irrigation pond, you are on time-of-use rates, and if you use an electric pump, fill the pond at night to take advantage of the cheapest electricity rates.

8. Many of the recommendations are low cost and easy to implement or incorporate into your operation and maintenance program.

For more information on the project, or if you are interested in a water assessment, please contact either Katie Gibb, Phoenix Solutions katie.gibb@phoenix-solutions.ca or Bruce Kelly at Farm & Food Care Ontario bruce@farmfoodcare.org.

Katie Gibb is project manager for Phoenix Solutions.

Add new comment